Description

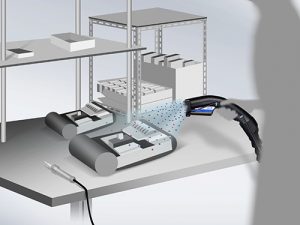

In today’s precision-driven industries like electronic manufacturing and medical device assembly, managing static electricity is critical to ensure product quality and reliability. Simco-Ion’s Top Gun? and orlON? ionizing air guns stand out as essential tools for maintaining optimal cleanliness and operational efficiency.

Overview of Top Gun? and orlON? Ionizing Air Guns

Simco-Ion’s Top Gun? ionizing air gun is engineered for high-performance static control. It boasts a balanced ion output of 0 ±15 V, facilitating rapid static charge dissipation to safeguard sensitive components. The gun’s design includes a stainless steel emitter and features like a flow control valve for adjustable airflow, ensuring precise application-specific settings.

Conversely, the orlON? is a nozzle conversion of the Top Gun?, retaining its robust ionization capabilities while focusing on direct, high-force airflow. Equipped with a replaceable 0.01 micron particle filter at its nozzle exit, the orlON? guarantees the delivery of clean air, vital for applications requiring meticulous cleanliness standards.

Key Features and Specifications

Both the Top Gun? and orlON? share common features designed to enhance usability and performance:

- Ergonomic Design: Lightweight and ergonomic, equipped with a comfortable light-touch trigger for extended use without operator fatigue.

- Integrated Controls: Includes built-in features like ionization indicator lights, allowing users to monitor operational status and ensure effective ionization at the target area.

- Environmental Adaptability: Operates effectively in a range of conditions (0 – 40oC, 30 – 60% RH), suitable for diverse manufacturing environments.

- Gas Input Options: Supports Clean Dry Air (CDA) or Nitrogen input, providing flexibility depending on application requirements.

Applications in Manufacturing and Assembly

The versatility of Simco-Ion’s ionizing air guns makes them indispensable across various industries:

- Electronic Manufacturing: Essential for preventing ESD (Electrostatic Discharge) damage during the assembly of delicate electronic components.

- Medical Device Manufacturing: Ensures cleanliness and static control in environments where product sterility and integrity are paramount.

- Precision Parts Assembly: Facilitates clean assembly processes, reducing particulate contamination and enhancing product quality.

- Optics and Molded Parts Cleaning: Ideal for removing dust and particulates from optical lenses or molded parts before finishing processes.

Enhanced Efficiency and Productivity

By integrating these ionizing air guns into manufacturing processes, businesses benefit from:

- Improved Product Quality: Minimized static charge ensures consistent product quality and reliability.

- Operational Efficiency: Reduced downtime due to ESD-related issues and enhanced workflow efficiency.

- Cost Savings: Optimized air consumption and extended equipment lifespan through efficient static control measures.

Simco-Ion’s Top Gun? and orlON? ionizing air guns exemplify innovation in static control technology, providing robust solutions for maintaining clean and static-free manufacturing environments. Their ergonomic design, coupled with advanced features and precise ionization capabilities, makes them indispensable tools for industries requiring stringent cleanliness and operational efficiency standards.

In conclusion, adopting Simco-Ion’s ionizing air guns not only enhances product integrity but also contributes to sustainable manufacturing practices by minimizing ESD-related waste and ensuring consistent high-quality output.

Reviews

There are no reviews yet.